Latest News and Updates from Passivent

Stay up to date with all our latest company news and product developments.

Full steam ahead for Passivent and Kingfisher at Isle of Man Ferry Terminal

Passivent and Kingfisher Louvres, subsidiaries of the Building Product Design group, have joined forces to deliver a full package of…

Find out more

Meet the team – James Hammick

Meet James Hammick, Business Development Manager for London and the South-East. Find out more here about his life in and…

Find out more

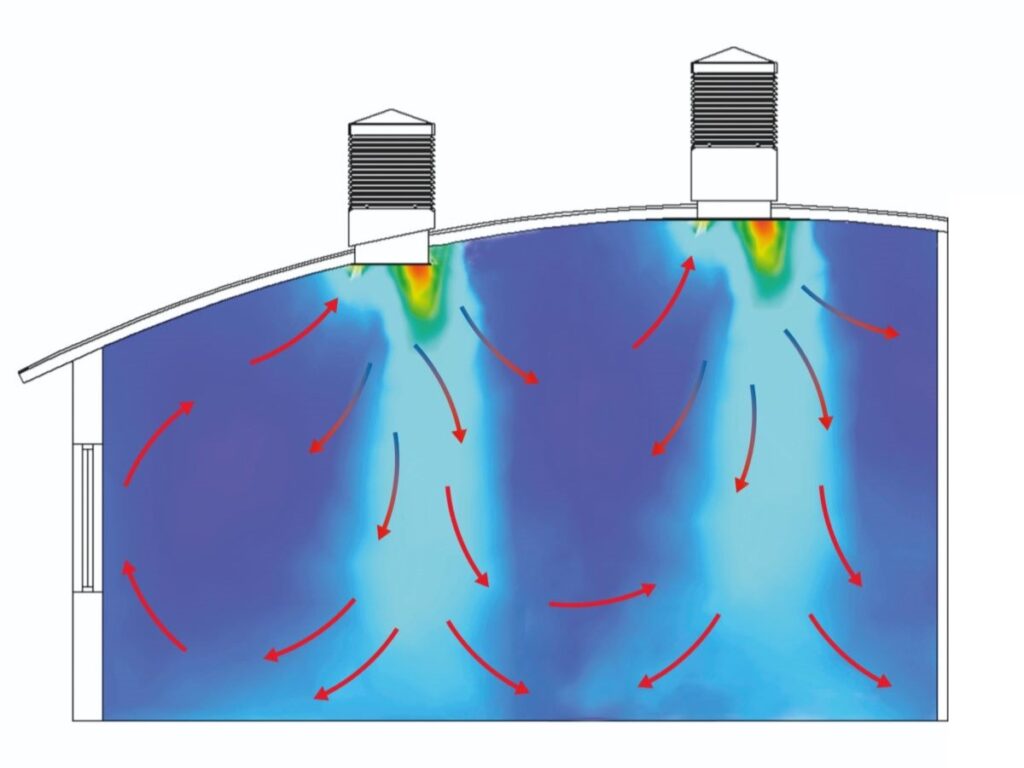

Simulating Passivent Natural Ventilation Roof Terminals in IESVE

Last year IES and Passivent partnered to allow users to quickly assign and analyse the effect of Passivent Roof Ventilation…

Find out more

Hybrid ventilation system for Vertis modular school building project

Passivent has supplied its hybrid ventilation system to Vertis for a new modular building at Sutton Valence School, one of…

Find out more

Passivent’s ventilation solutions are top of the class

Passivent has supplied a combination of Hybrid Plus2 Aircool ventilators and Hybrid Plus Airstract roof ventilation terminals for a new…

Find out more

A year of supporting specifiers with energy efficient ventilation strategies

In our milestone 40th anniversary year we’ve delivered our range of natural and hybrid ventilation solutions to projects across the…

Find out more

Natural ventilation for York Street Station’s footbridge, Belfast

Passivent’s controllable Aircool ventilators provide natural ventilation for York Street Station’s footbridge in Belfast.

Find out more

Passivent plays its part in new passivhaus school

Passivent has supplied its patented SoundScoop® acoustic cross-talk attenuators for use in the new Pembrey School in Wales.

Find out more

Glidevale Protect and Passivent at the Architecture and Building Expo, RDS in Dublin.

On October 9th and 10th, we're presenting architects with our full range of manufactured solutions for the building envelope.

Find out more

40th anniversary post

In July we celebrated a major milestone for the business – our 40th anniversary! Ever since our inception in 1984,…

Find out more

Meet the team – Ed Richmond

For our third ‘Meet the team’ of 2024 we invited Ed Richmond, Regional Sales Manager, to tell us a bit…

Find out more

Passivent hits natural ventilation targets for Sport England’s new archery centre

Passivent, one of the UK’s leading manufacturers of natural and hybrid ventilation solutions, has supplied eleven Airscoop® roof mounted terminals…

Find out more