WestQuay Watermark is a premium leisure and dining hub located on a redeveloped brownfield site in the city centre of Southampton.

Formerly a Pirelli factory, the £85m centre plays an important part in Southampton’s environmental and economic regeneration and is home to over 20 restaurants, a multiplex cinema and a bowling alley as well as a new public plaza in front of the city’s historic walls.

With a ‘BREEAM Excellent’ rating, the building’s unique cladding and cantilever design has created an architectural landmark on the south coast. Following the granting of planning permission in February 2014, the scheme was completed in February 2017.

The challenge

The development’s unique architectural design posed particular challenges in designing and delivering the ideal ventilation strategy.

These challenges included the need for an effective ventilation system that did not compromise the aesthetically pleasing design, by integrating seamlessly with the uniquely faceted construction of the building. At the same time the system had to be energy efficient, cost-effective and low maintenance. The requirement for the free movement of air to provide a comfortable internal space for users was complicated by the large expanse of glazing used in the design of the building, making overheating a real concern.

Timing was also important due to the nature of the building design, the complex build programme, the multiple trades involved and the need to minimise the risk of damage on site.

Flexibility was another key stipulation, with the chosen system needing to react to the continually changing environment inside the centre such as daytime and night-time temperatures and also the varying levels of footfall. Finally, Southampton’s location would mean that the product would need to be robust to protect against the coastal elements.

The solution

To satisfy the natural ventilation requirement, a robust ventilation strategy using Passivent Aircool® controllable ventilators was specified by consultants Hoare Lee. The installation of the ventilation system was managed by building envelope company Lakesmere who was employed to install the roof and curtain wall packages, plus a host of architectural features and ancillaries.

Passivent collaborated with a multi-functional team from Lakesmere to ensure the design fully met Hoare Lee’s specification. Passivent’s technical team supported Lakesmere in calculating the quantity and size of ventilators needed to meet the total free area of 44.54m², as well as producing bespoke drawings for a total of 157 Aircool ventilators supplied across eight different curtain walling screens in various areas of the development. The complex project needed significant programme management by Passivent who liaised with Lakesmere to ensure that the ventilators were manufactured and delivered on time and in the volumes required to enable the phased build. Thanks to a well-managed design period at the beginning of the project, installation on site ran smoothly and ensured that the risk of product damage whilst on site was minimised.

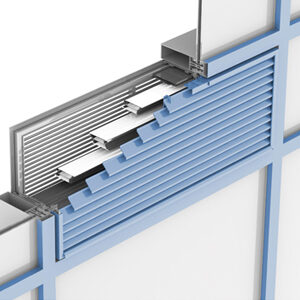

The Aircool ventilators were installed at both high and low levels within the curtain walling façade to ensure a good through-flow of air. Passivent also supplied a number of ‘blank’ units for continuity of appearance where there was no need for actual ventilation. Aircool units were designed to suit the multi angled façade, with bespoke louvres custom manufactured to suit the faceted curtain walling system.

A key reason for choosing the Aircool ventilation range was its ability to continuously adjust the airflow by means of low voltage, modulating actuators, which constantly control the air and CO₂ levels in the space to match the changing internal environment. The system includes removable actuator covers for ease of maintenance. Aircools are manufactured from aluminium with ABS thermal breaks and specifically for the WestQuay development, marine grade powder coating with a 25 year guarantee was used to provide a robust and weather resistant finish.

Nick Beswick, Sales Director at Passivent said, “Aircool is ideal for installation in external façades such as WestQuay. It is discrete and, compared to mechanical ventilation, is cost-effective to install, adaptable and requires minimal maintenance.” Beswick continued, “Aircool is particularly favoured for many projects due to its ability to be integrated within a building management system. This project demonstrates that the Aircool is a highly flexible product and offers designers greater scope within the ventilation and control strategy they employ.”

Colum Ellard, Lakesmere’s glazing manager said, “Passivent’s Aircool looks great both internally and externally and the finish was excellent. The Passivent team ensured that the ventilators were delivered on time and in the quantities and sizes needed for each phase of the build.” He continued, “The Aircool’s design meant that the ventilators were very straightforward to install and the ability to seamlessly integrate them within the building management system was a real benefit.”